- 48h delivery

- +49 231 2222 3001

- Dealer search

C-parts often account for less than 10 % of total purchasing volume – yet they generate over 50 % of operational procurement costs. Ordering by phone, relying on handwritten notes or forgetting to reorder wastes time, money and energy. With intelligent supply technology, digital processes and personal consulting, TECWERK specialist trade partners help companies make their C-parts procurement more efficient, transparent and future-proof.

C-parts are small, inexpensive, yet essential items, such as PPE, tools, screws and consumables. Although they are low in cost, they are indispensable for daily operations. Without structured processes, manual ordering can quickly lead to bottlenecks, overstocking or unnecessarily high process costs.

A professional C-parts management solution ensures order and predictability. It enables the intelligent control of procurement, storage and replenishment – through automated, digitally connected processes perfectly tailored to your needs. The result: reliable supply with minimal effort.

The advantages for you at a glance

Digitalisation as a driver of efficiency

Modern, digital C-parts management creates clear structures and sustainably reduces process costs. Automation, system integration and the use of intelligent technologies boost the efficiency of ordering, replenishment and inventory management – while also ensuring a seamless supply chain.

Digital solutions make it possible to trace every withdrawal, monitor stock levels in real time and trigger reorders automatically. This gives you a full overview of your material consumption at all times, ensuring reliable supply – with no need for manual monitoring.

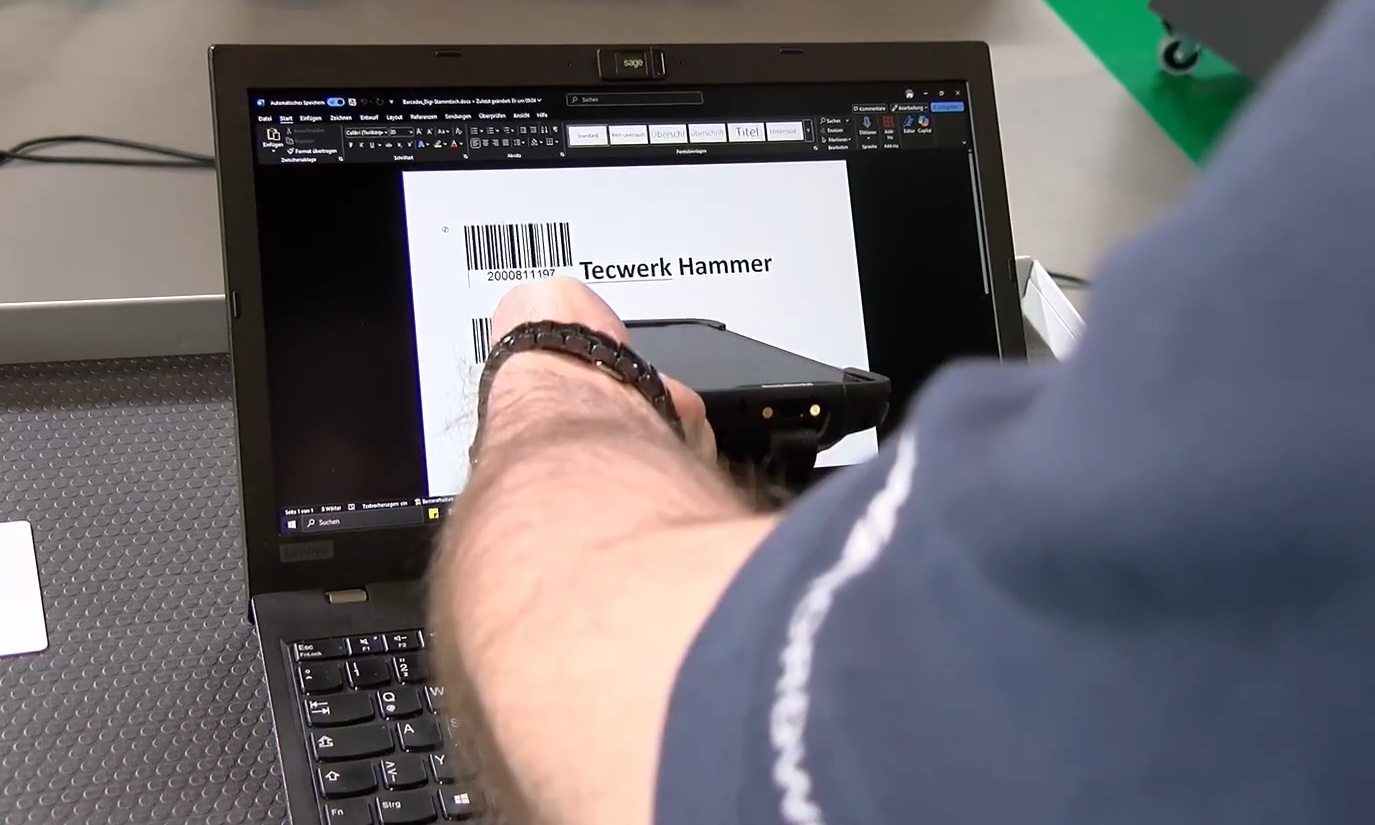

Innovative systems such as eVEND vending machines, ScanWerk ordering systems or the new i.cupboard make supply simpler than ever before. Whether material dispensing directly at the workplace, mobile ordering solutions or digital interfaces to your ERP system – automated procurement increases efficiency and transparency across all areas.

i.Cupboard 4.0

ScanWerk

Rotoflex SupplyPoint

With TECWERK, you are choosing efficiency, innovation and practical expertise. Our specialist dealers support you in digitalising your C-parts procurement – with individually tailored system solutions, personal consulting and technical competence.

Together, we will make your processes simpler, more transparent and more economical – giving you more time to focus on what truly matters: your core business.

How can I reduce procurement process costs?

A structured management system reduces the effort required for ordering, prevents shortages and saves costs. With a C-parts system such as eVEND (TECWERK) combined with the ScanWerk ordering system, you can simplify your processes:

- Scanners capture articles via barcode instead of manual input

- Vending machines provide 24/7 access with automatic restock notifications

- Automated processes significantly reduce the need for manual intervention

How can I automate recurring orders?

Digital systems such as vending cabinets or scanner solutions automatically monitor stock levels and trigger reorders – quickly, transparently and without errors. Consumption data is recorded automatically and used to generate restock notifications and orders. Ideally, this is directly linked to ERP systems to eliminate any further manual effort.

What are the costs of inefficient C-parts management?

Manual processes ultimately lead to high costs, delays and a lack of transparency – often considerably outweighing the reduction in material costs achieved.

Which systems are suitable for my industry?

Whether for industry or trades – eVEND is ideal for production companies, workshops and businesses in the skilled trades alike. It can be combined with other systems (locker, carousel or load cell vending machines) and with ScanWerk for flexible use.

Which products can I provide with vending machines?

Many products from the extensive TECWERK assortment – for example protective gloves, tools, cutting tools, measuring instruments and more.

Do you support e-procurement (electronic purchasing)?

Yes. We offer automated data transfer, digital documents (invoices, orders) and EDI or OCI integration – everything required for modern e-procurement.

What items are considered C-parts?

C-parts are low-value articles that are nevertheless required on a regular basis – such as screws, tools, personal protective equipment or consumables. They often make up the largest share of procurement transactions.